Laboratory

Diaswiss instruments offer state-of-the art solutions for almost any laboratory application enabling users to work efficiently both from a technical and an economic perspective. Development and manufacturing of our laboratory instruments follows the strictest quality standards using the latest manufacturing technologies.

The technical specifications of the instruments in terms of cutting geometries, crosscuts or diamond coatings are strictly driven by the technical application needs. Intelligent design of the working parts reduces the need for frequent instrument change. We are confident that this will help you deliver outstanding results in your daily work.

- Carbide burs

- Electroplated Diamonds

- Sintered Diamonds

- Discs

- Zirconia tools

- Polishers

- Kits & Accessories

- Consumables

Diaswiss carbide instruments leave nothing to be desired in terms of durability, cutting efficiency as well as surface quality. In addition to simple and cross-cut designs, Diaswiss offers a range of innovative cuts for specific materials and applications. The manufacturing process of these instruments is characterised by special quality features, which directly benefit the user. This includes the complex carbide soldering process, during which the shank is inserted into the carbide head, resulting in significantly greater stability, reduced risk of breakage and exemplary running smoothness.

The Diaswiss range of electroplated diamonds consists of tools for various applications, specifically ceramics. We source specially selected natural diamonds to ensure maximum cutting power. Our diamonds are multi-layered and individually embedded to provide a superior cutting experience. Although this production process is complex, we deem it necessary in order to produce consistent quality which exceeds your expectations.

The ‘Diamass’ range comprises several particularly powerful sintered diamonds with coarse and extra-coarse diamond grit, as well as a broad selection of instruments in fine and superfine grit. In conjunction with a high diamond concentration which is progressively exposed throughout the grinding process, the specially developed metal bond results in significantly improved tool life and cutting power.

The implementation of sintered diamonds is particularly recommended in regards to non-precious metals, specifically partial frameworks (extra coarse to fine), as well as ceramics (fine to superfine).

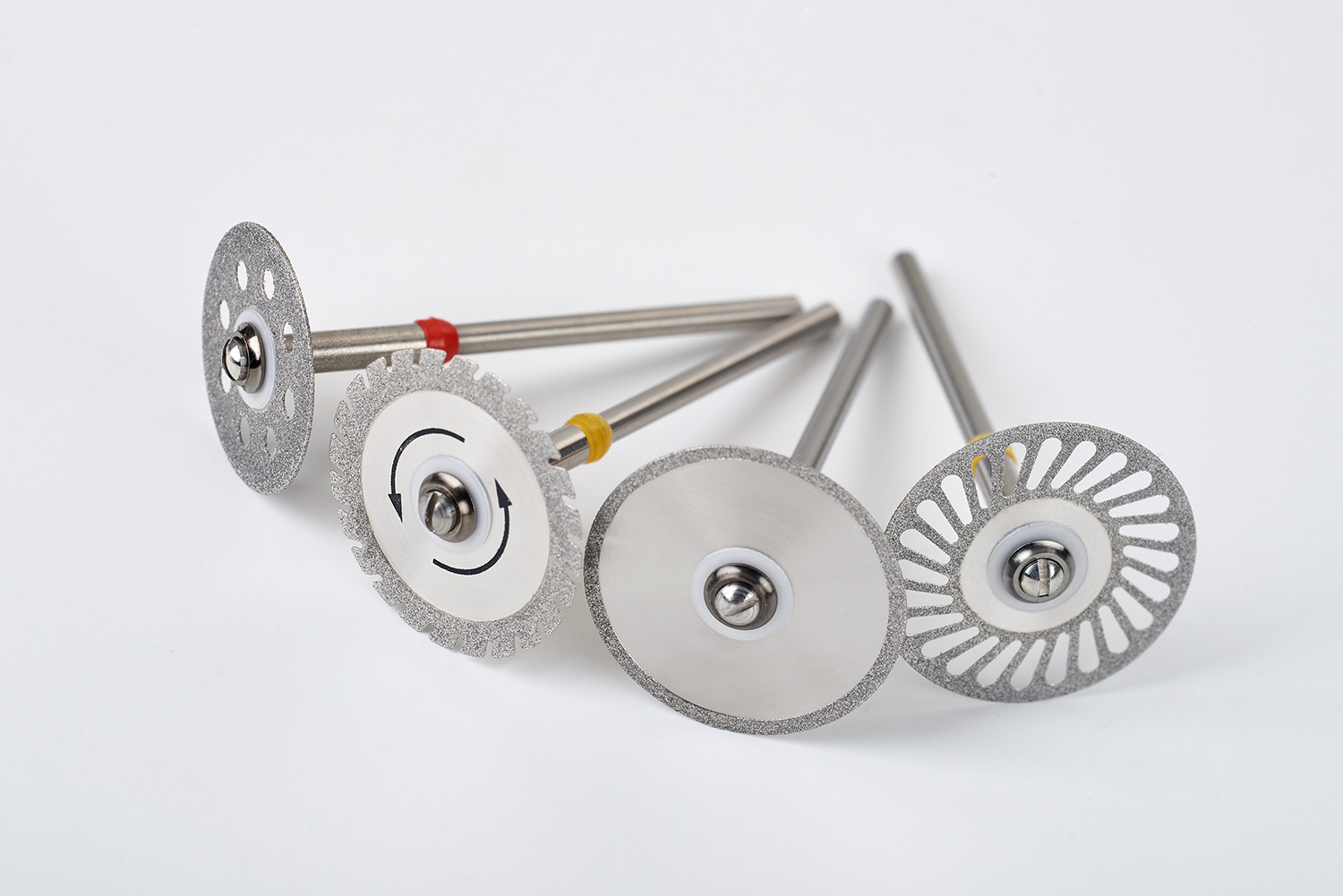

Diaswiss’ range of discs includes diamond discs for ceramics, plaster cutting discs, and separating discs for metals. Distinctive disc strengths and perforated designs enhance the product line. The high-quality manufacturing process ensures exceptionally smooth running and longevity.

Diaswiss offers a range of innovative tools for working zirconia within hydro air carvers for both hand piece and parallel milling. Diazircon tools allow straightforward and constructive working of zirconia, in many cases without the need for water cooling if handled correctly. Due to the porosity of the bonding and the selection of the diamond grit, heat generation is kept to a minimum. Alongside coarse grit instruments for rapid trimming, we offer medium grit instruments (for abrasion und pre-polishing), as well as fine grit polishers.

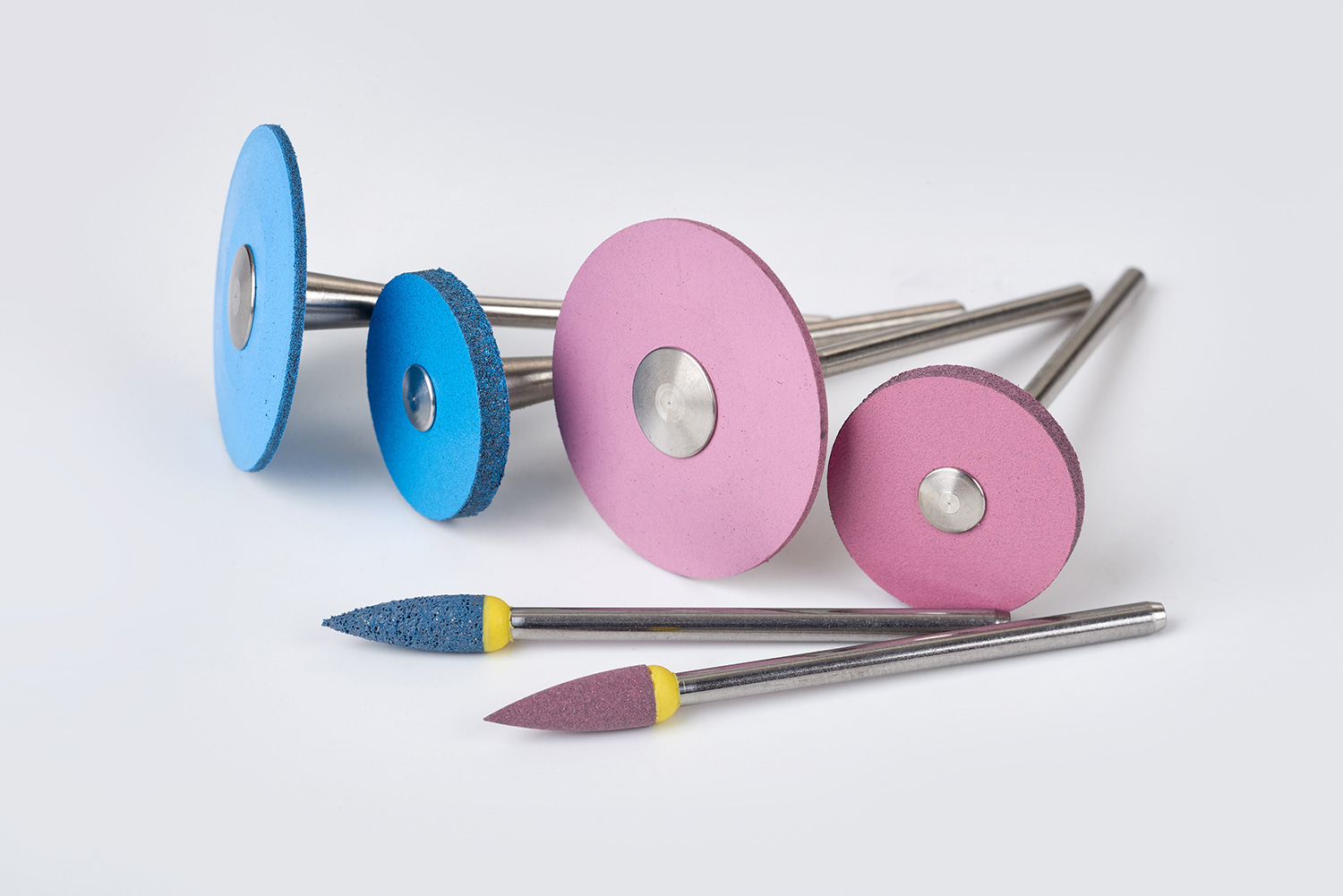

Diaswiss offers an assortment of polishers that you can use to work on ceramics, partial dentures, metal, as well as acrylics and titanium. Our range of polishers will allow you to obtain a perfect and high gloss finish of the worked surfaces

Diaswiss offers an assortment of polishers that you can use to work on ceramics, partial dentures, metal, as well as acrylics and titanium. Our range of polishers will allow you to obtain a perfect and high gloss finish of the worked surfaces Our full range of Diaswiss kits: Model Preparation Kit, Lithium disilicate / Zirconia Kit, Composite Kit, Acrylics Kit, Precious alloys Kit, Non-precious alloys Kit, Ceramics Kit, and Partial framework Kit. Our range of accessories comprises bur blocks with 24, 48, and 72 holes for HP instruments.

Our full range of Diaswiss kits: Model Preparation Kit, Lithium disilicate / Zirconia Kit, Composite Kit, Acrylics Kit, Precious alloys Kit, Non-precious alloys Kit, Ceramics Kit, and Partial framework Kit. Our range of accessories comprises bur blocks with 24, 48, and 72 holes for HP instruments.

We offer a wide range of consumables for the dental laboratory. Diaspacer, available in several colours in 25ml bottles. Debubblelizer, wax and silicone expander for a perfect and bubble-free reproduction of your models. Silicone spray, Ceramspray is a silicone-free separation spray. Occlusion spray for locating contact points. Diascan spray, an extremely fine spray for the preparation of scanning surfaces.

Our Diaswiss carbide cutters cover all relevant applications within the dental lab including metal alloys, acrylics, composites, partials, titanium, and zirconia available in a variety of shapes, diameters, and lengths.

Our Diaswiss carbide cutters cover all relevant applications within the dental lab including metal alloys, acrylics, composites, partials, titanium, and zirconia available in a variety of shapes, diameters, and lengths.  Our Infiniti carbide burs are coated in power nitride using the latest coating technology. This significantly enhances the instruments’ lifetime compared to conventional coatings by reducing friction resistance without the loss of cutting efficiency.

Our Infiniti carbide burs are coated in power nitride using the latest coating technology. This significantly enhances the instruments’ lifetime compared to conventional coatings by reducing friction resistance without the loss of cutting efficiency. Diaswiss lab carbide burs are a winning solution for all applications. This product range is characterised by its outstanding cutting efficiency, running smoothness, and longevity. The variety of shapes and cutting geometries reduce frequent instrument changeover, thereby saving time and money.

Diaswiss lab carbide burs are a winning solution for all applications. This product range is characterised by its outstanding cutting efficiency, running smoothness, and longevity. The variety of shapes and cutting geometries reduce frequent instrument changeover, thereby saving time and money. Diaswiss offers instruments for the milling technique available in various crosscuts. In combination with an array of special instruments and polishers, we provide a practical range of instruments for parallel milling at 0° as well as 2°, 4° and 6°, which are suitable for all relevant milling technique applications.

Diaswiss offers instruments for the milling technique available in various crosscuts. In combination with an array of special instruments and polishers, we provide a practical range of instruments for parallel milling at 0° as well as 2°, 4° and 6°, which are suitable for all relevant milling technique applications. Diatrim is an instrument specifically developed for grinding plaster models with low vibration, whereby the diamond coating design prevents clogging.

Diatrim is an instrument specifically developed for grinding plaster models with low vibration, whereby the diamond coating design prevents clogging. The wire brush wheel is a distinctly coated diamond instrument to be used on stippled partial surfaces.

The wire brush wheel is a distinctly coated diamond instrument to be used on stippled partial surfaces. Sintered diamonds are used predominately on partial frameworks, as their characteristics and performance deliver significant advantages compared to conventional stones. Another application for sintered diamonds is ceramics where they are appreciated because of their exceptionally long lifetime. Most importantly, their lifetime is about 200-300 times longer than that of stones.

Sintered diamonds are used predominately on partial frameworks, as their characteristics and performance deliver significant advantages compared to conventional stones. Another application for sintered diamonds is ceramics where they are appreciated because of their exceptionally long lifetime. Most importantly, their lifetime is about 200-300 times longer than that of stones.  The primary use of sintered diamond discs is for partial frameworks as the high diamond concentration enables superior cutting power and longevity.

The primary use of sintered diamond discs is for partial frameworks as the high diamond concentration enables superior cutting power and longevity. Diaswiss plaster cutting discs feature a special design for maximum cutting efficiency in a variety of diameters, as well as multiple layers of natural diamonds.

Diaswiss plaster cutting discs feature a special design for maximum cutting efficiency in a variety of diameters, as well as multiple layers of natural diamonds. Our range also contains highly efficient cutting discs for separating metals with an extensive operating time.

Our range also contains highly efficient cutting discs for separating metals with an extensive operating time. We offer Diazircon coarse for contouring and shaping zirconia, Diazircon medium for pre-polishing zirconia and finally Diazircon polish for mirror polishing zirconia. .

We offer Diazircon coarse for contouring and shaping zirconia, Diazircon medium for pre-polishing zirconia and finally Diazircon polish for mirror polishing zirconia. . Our gold-plated HP instruments for zirconia consist of specially selected diamonds specifically suited for working zirconia. Diaswiss HP diamonds for zirconia require water cooling.

Our gold-plated HP instruments for zirconia consist of specially selected diamonds specifically suited for working zirconia. Diaswiss HP diamonds for zirconia require water cooling. Diamill – our innovative tool for working zirconia within a hydro air carver for both hand piece and parallel milling.

Diamill – our innovative tool for working zirconia within a hydro air carver for both hand piece and parallel milling. Diaceram 2-step – our two-step polishing system for ceramics, comprising diamond-impregnated polishers for polishing, finishing, and high-shine.

Diaceram 2-step – our two-step polishing system for ceramics, comprising diamond-impregnated polishers for polishing, finishing, and high-shine. Diametal – our two-step polishing system for partial framework and precious alloys comprising polyurethane polishers with silicone carbide.

Diametal – our two-step polishing system for partial framework and precious alloys comprising polyurethane polishers with silicone carbide. Diacryl Pol – our two-step silicone-based polishing system for acrylics.

Diacryl Pol – our two-step silicone-based polishing system for acrylics. Diatitan – our three-step polishing system for titanium comprising diamond-impregnated polishers with silicone carbide.

Diatitan – our three-step polishing system for titanium comprising diamond-impregnated polishers with silicone carbide. Diabrush – our polishing brushes for metals (steps 0 to 2), ceramics (steps 3 to 4), and composites/acrylics (steps 4 to 5). Their brush texture enables simple polishing of all surfaces including occlusal and interdental surfaces. Please note: intermittent pressure and circular polishing movements are recommended.

Diabrush – our polishing brushes for metals (steps 0 to 2), ceramics (steps 3 to 4), and composites/acrylics (steps 4 to 5). Their brush texture enables simple polishing of all surfaces including occlusal and interdental surfaces. Please note: intermittent pressure and circular polishing movements are recommended. Our range of polishing paste comprises DIASWISS Superbright and DIASWISS Powerpaste, for high-shine polishing of all types of dental ceramics, especially full ceramics such as lithium disilicate or zirconia. Both contain an extremely high concentration of diamonds, to be used with our goat hair brush, felt or similar.

Additionally, Diaswiss’ polishing compound is available as a super-finishing compound for resins, CoCr, precious alloys, and titanium.

Our range of polishing paste comprises DIASWISS Superbright and DIASWISS Powerpaste, for high-shine polishing of all types of dental ceramics, especially full ceramics such as lithium disilicate or zirconia. Both contain an extremely high concentration of diamonds, to be used with our goat hair brush, felt or similar.

Additionally, Diaswiss’ polishing compound is available as a super-finishing compound for resins, CoCr, precious alloys, and titanium. Die spacers serve as placeholders for fixation materials (such as cement) on crown- and bridgework. Diaswiss’ Diaspacer is available in a variety of colours relating to its respective thickness. It provides excellent bonding, even coverage, and is scratch resistant with short drying time.

Die spacers serve as placeholders for fixation materials (such as cement) on crown- and bridgework. Diaswiss’ Diaspacer is available in a variety of colours relating to its respective thickness. It provides excellent bonding, even coverage, and is scratch resistant with short drying time. This extra-fine Diaswiss occlusion spray is available in several colours. The spray allows for easy marking of contact points on prosthetic works and crowns. It is distinguished by its ease of control incl. tube nozzle, as well as its easy removal by brush or steam-jet. Insoluble in water or alcohol.

This extra-fine Diaswiss occlusion spray is available in several colours. The spray allows for easy marking of contact points on prosthetic works and crowns. It is distinguished by its ease of control incl. tube nozzle, as well as its easy removal by brush or steam-jet. Insoluble in water or alcohol.  Diaswiss’ scanspray is an ultrafine spray for the preparation of surfaces for CAD/CAM scanning, as well as friction testing on telescopic crowns and attachments. Facilitates easy removal by brush and is insoluble in water and alcohol.

Diaswiss’ scanspray is an ultrafine spray for the preparation of surfaces for CAD/CAM scanning, as well as friction testing on telescopic crowns and attachments. Facilitates easy removal by brush and is insoluble in water and alcohol. Diaswiss Debubblelizer is our silicone and wax wetting agent, which facilitates precise bubble-free plaster/investment models made of silicone and other impression or duplicating materials. It is not compatible with alginates and hydrocolloids and evaporates without residue, featuring a short drying time. Avoid the formation of puddles.

Diaswiss Debubblelizer is our silicone and wax wetting agent, which facilitates precise bubble-free plaster/investment models made of silicone and other impression or duplicating materials. It is not compatible with alginates and hydrocolloids and evaporates without residue, featuring a short drying time. Avoid the formation of puddles.